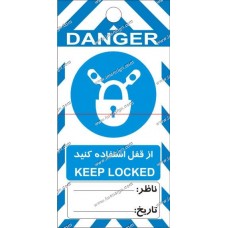

تگ ایمنی

مشخصات تگ ایمنی تولیدی ایمن ساین:

سایز استاندارد :cm20*10

دارای بست کمربندی پلاستیکی

برش گرد لبه های تگ ایمنی (فاقد لبه ی تیز و برنده)

ایمنی بالا (به دلیل نصب برچسب بر روی آن، در صورت شکستن تگ ایمنی از پاشش تکه و پاره های آن به اطراف جلوگیری می شود. )

سبک

طراحی مهندسی و زیبا

نصب آسان بر روی اکثر سطوح

ضخامت کم (3 میلیمتر) و استحکام بالا

استفاده از مرغوبترین ورق اکلریک موجود در ایران

سه سال ماندگاری در برابر نور آفتاب (استفاده از رنگ های سالونت مقاوم در برابر UV)

تگ ایمنی دارای روکش لمینت جهت ماندگاری رنگ ها

تگ های ایمنی قابل شستشو هستند

نارسانا (جهت ایمنی بیشتر در موارد تگ گذاری تاسیسات برقی)

تولید تگ های ایمنی در ابعاد و طرح های مورد نظر شما مشتریان گرامی امکان پذیر است.

Safety

Equipment

Standards

Your Keys to

Business Success

The International Safety Equipment Association (ISEA) consists of companies that make hundreds of different types of equipment to protect the safety and health of people who are doing work. Members’ products include hard hats, safety eyewear, hearing protectors, work gloves and shoes, respirators, fall protection, high- visibility and protective apparel, first-aid kits, emergency eyewashes and showers, environmental monitoring instruments and warning devices.

These pieces of equipment are essential to the safety and health of workers in every manufacturing, mining and construction sector, as well as law enforcement, fire service, health care, laboratories, on the farm, around the home, and around the world.

This booklet is intended to provide ISEA members

and key stakeholders with an overview of U.S. and international safety equipment standards, and why

it is essential for companies to participate in their development and promotion.

Contents

2 Introduction

4 U.S. S tandards

4 What is a safety equipment standard?

5 Where do standards come from?

5 What is ANSI?

6 What is ISEA’s involvement in the development of ANSI standards for safety equipment?

6 Why is it important for safety product manufacturers to be involved in the development of standards?

6 What would my company be expected to do in the development of safety equipment standards that ISEA publishes?

7 Is there a cost to participate in standards development beyond the basic ISEA membership fees?

7 Can ISEA members become involved in the development of safety equipment standards for which ISEA is not responsible?

8 International S tandards

8 What is the ISO and what is its role in setting safety equipment standards?

9 Why are ISO standards keys to business success?

10 Does my company have the opportunity to participate in the development of ISO standards and, if so, how?

10 How do ISO standards for safety equipment fit with ANSI standards?

11 Where can I get a list of safety equipment standards around the world?

11 Conformity Assessment

Safety Equipment Standards

Your Keys to Business Success

S

“Today’s world economy creates an environment where standards compliance is not an option — it’s a requirement… A world without standards would be chaotic at best and dangerous at worst.” 1

afety equipment is essential to protect people against hazards in the workplace.

It is the first line of protection against falling and flying objects, chemicals and vapors, noise, electricity or heat. It is a suit or glove, a helmet or goggles, a respirator or hearing protector, a fall-arrest system or environmental monitoring instrument. It is the only thing that makes it possible to work in many environments and the best option for working in many others.

Personal protective and safety equipment is technically sophisticated, designed, built and tested to exacting standards of performance. These product standards are the backbone of consistent, reliable safety equipment. Manufacturers use them to determine the performance requirements for products they design, make and sell, and the test procedures to assess conformity to those requirements.

Introduction

1“Why Standards Are Important,” IHS, Inc., Englewood, Colo.,www.ihs.com.

2

Safety Equipment Standatanda tandards : Your Keys to eys to Business Success

Sellers, purchasers and users need them to select the right product for the job, and understand its application and limitations. Government agencies incorporate them into workplace safety and health regulations.

Safety equipment standards are important because they establish and define a minimum level of performance that a particular type of safety equipment will provide for its intended uses. Standards convey information to the buyer consistently and understandably. Standards promote compatibility of components and systems. F or the manufacturer or seller of safety and personal protective equipment, product standards are the keys to business success.

3

INTERNATIONAL SAFETY EQU IPMENT ASSOCIATION

1

4

Safety Equipment Standatanda tandards : Your Keys to eys to Business Success

U.S. Standards

“As a medium-size company, we simply had to get involved in the process of trying to influence the writing of standards, and of understanding what the issues really are. …If you are not involved in standards or standards-setting, you will be left outside and the competition will run away with your business.”

— J. Hans Kluge, chairman, Automatic Switch Co., from “You, Your Customers and ISO 9000: Part Three,” The Business F orum Online®.

What is a safety equipment standard?

A safety equipment standard is a document (1) established by consensus and (2) approved by a recognized body that (3) provides rules, guidelines or characteristics for a safety product or process for common and repeated use:

l Consensus means that standards come from a process designed to make sure everyone’s voice is heard, everyone’s opinion is considered, and conflicts are resolved where possible. It does not mean everyone agrees with everything in the final standard, but that all agree to accept the final result.

l A recognized body can be any government agency or organization set up to manage and approve the standards process that is given that recognition by some governing authority, such as a national government or regulatory agency.

l Rules, guidelines and characteristics for common and repeated use are the guts of the standard — the specifications, classifications, test procedures and usage guidelines that enable users to evaluate that a product meets the established level of performance.

Voluntary standards, such as those developed by the ISEA, are most common and share certain important principles. They are established by consensus. They must be impartial, and not favor one manufacturer’s product over another, and they establish a baseline of performance. This means that manufacturers can offer a range of products that compete on design, comfort, fit, durability, appearance, cost and services, all of which offer the same basic protection.

2

3

Where do standards come from?

Standards are written by manufacturers and users, government officials, experts, academics — anyone with knowledge of the product, process or service, an understanding of how to establish common performance characteristics and guidelines, and a willingness to participate in the process.

Government standards, such as National Institute for Occupational Safety and Health (NIOSH) respirator specifications and U .S. Occupational Safety and Health Administration (OSHA) workplace standards, are developed through a formal rulemaking process and are the law of the land.

F

ar more common are the consensus standards developed by volunteers from trade associations such as ISEA, professional societies such the American Society of Safety Engineers (ASSE) or the American Industrial Hygiene Association (AIHA), and standards-developing organizations such as ASTM International or the National F ire Protection Association (NFPA).

What is ANSI?

Many of these consensus product standards achieve recognition as American National Standards through ANSI – the American National Standards Institute. F ormed by standards writers and users, ANSI is a federation that manages the voluntary standards system in the U nited States. ANSI does not develop standards or approve products. R ather, its role is to coordinate the activities of organizations in the U nited States, such as the ISEA, that do develop and publish standards. ANSI is not a government agency, although it is the official U .S. voice in international standards bodies and works closely with the government. It accredits standards-developing organizations and standards committees, which follow rules and procedures established by ANSI to ensure balance, consensus and relevance.

5

INTERNATIONAL SAFETY EQU IPMENT ASSOCIATION

4

5

6

What is ISEA’s involvement in the development of ANSI standards for safety equipment?

ISEA brings together manufacturers to draft product standards, manages the consensus process for their approval as American National Standards, publishes and sells the standards, and interprets them for producers, users and regulators. ISEA also identifies the need for new standards and sets in motion the process through which they are developed. This need may stem from new product lines, new technologies or new materials in the marketplace, and often reflects desires of end-user communities to address their needs. After a standard is drafted or updated, ISEA submits it for review, comment and approval by stakeholders. You can find a list of the current standards that ISEA publishes at www.safetyequipment.org.

Why is it important for safety product manufacturers to be involved in the development of standards?

If your company makes a product that has to conform to a particular standard, then it makes business sense for your company to take part in the development of that standard. It is how your company can have a say in the characterization, specifications, guidelines and performance requirements for the products you manufacture. Manufacturers who do not participate in standards development are subject to the consensus of those companies who are involved in drafting the standard. As a member of an ISEA product group, your company automatically has a seat at the standards-development table.

In other words, if you want to make sure your products or services meet the standard, write it.

What would my company be expected to do in the development of safety equipment standards that ISEA publishes?

As a member of ISEA, your company would supply technical, engineering and product expertise to help develop and refine the standards that apply to products that your

6

Safety Equipment Standatanda tandards : Your Keys to eys to Business Success

7

8

company manufactures. ISEA members typically propose changes concerning what the standard should or should not include, they review technical requirements and propose new ones, help identify research advances, and attend meetings where the issues are discussed and resolved. ISEA standards-development activities are coordinated by ISEA’s technical director and manager of standards programs.

Is there a cost to participate in standards development beyond the basic ISEA membership fees?

No. ISEA’s fee structure is designed to cover the costs of standards development as a part of product group fees. Beyond the dues and product group fees, the other financial obligations are time and travel to participate in meetings.

ISEA develops standards by the most efficient means possible, meaning that typically product groups meet in conjunction with other functions that members already are attending. In other words, we go to where they are located for other purposes to accomplish multiple tasks, thus minimizing travel expenditures. One exception is the annual ISEA F Fall Meeting, usually held in November in the Washington, D.C., area, when most product groups meet.

Can ISEA members become involved in the development of safety equipment standards for which ISEA is not responsible?

Yes. ISEA has official representation on all American standards-writing committees for personal protective equipment, as well as committees that establish the U .S. position on international standards. In many cases, these representatives are member-company experts. When they sit on other committees as representatives of ISEA, they must vote the consensus of the ISEA product group.

7

INTERNATIONAL SAFETY EQU IPMENT ASSOCIATION

1

International Standards

“The international language of commerce is standards.

Adherence to agreed-upon product or service specifications underpins international commerce, enabling trillions of dollars

of goods to flow across borders, regardless of the spoken

language of any business parties. The common acceptance of standards is fundamental to the success of robust, fair and free trade. Without standards, it would be difficult to imagine the

tremendous volume and complexity of international trade.”

– Donald L. Evans, former Secretary of Commerce, from Standards

and Competitiveness: Coordinating for R esults (2004).

ndeed, global commerce thrives on standards compliance. The U .S. Department of Commerce estimates that standards impact 80 percent of world commodity trade. Global standards establish a common language for product designers, manufacturers, sellers, purchasers and users worldwide. When it comes to safety equipment, international standards are key factors in enabling manufacturers to make products that are competitive around the globe, thus ensuring market access to save lives and prevent injuries worldwide.

Some American standards have achieved international recognition. They are developed in an open process that meets the requirements of international treaty organizations, and they are used globally. There also are international organizations that develop and promote global standards. F or safety and personal protective equipment, the most important of these is the International Organization for Standardization (ISO).

What is the ISO and what is its role in setting safety equipment standards?

The ISO — International Organization for Standardization — is a non-government organization responsible for developing and coordinating international standards. ISO’s Central Secretariat is in Geneva, Switzerland,

8

Safety Equipment Standatanda tandards : Your Keys to eys to Business Success

I

2

where it represents a network of national standards institutes, including ANSI, in 157 countries on the basis of one member per country. ISO standards for safety equipment are growing in importance because more countries use them as the basis for their domestic regulation of workplace protection. ISO standards benefit the countries where they are used, the manufacturers who sell products in those countries, and the end users of those products. Much more background information about ISO may be found on www.iso.org.

Why are ISO standards keys to business success?

R

ight now, standards for safety equipment in the U nited States differ from those in Europe, which differ from those in Japan, which differ from those in Australia, which differ from those in Brazil, and so forth. If your company wants to sell products in many different countries, you must either (1) design a product that meets all of the standards or (2) design different products to meet standards of each country.

As countries with emerging economies contemplate safety equipment standardization, increasingly they look to international standards to adopt as their national standards. Companies that sell products into countries that adopt ISO standards only have to design products that comply with that one standard to compete in all of those countries. And users in all of those countries know that the safety equipment they are using meets a minimum level of performance that has been established by a world body of experts.

Numerous ISO standards for safety equipment are in development under the technical committee — TC94 — that is responsible for the development of standards for “Personal safety — Protective clothing and equipment.” TC-94 subcommittees are working on head protection (SC1), foot protection (SC3), personal equipment for pro9

INTERNATIONAL SAFETY EQU IPMENT ASSOCIATION

4

3

tection against falls (SC4), eye and face protection (SC6), hearing protection (SC12), protective clothing (SC13), fire-fighters’ personal equipment (SC14), and respiratory protective devices (SC15). These subcommittees have work groups for specific products under the broader groupings. The level of ISO standards-drafting activity in the area of safety equipment has never been higher.

Does my company have the opportunity to participate in the development of ISO standards and, if so, how?

Voting members of ISO technical committees are countries. ANSI is the official voting representative for the United States. ISEA and its members have seats on U .S. Technical Advisory Groups (TAGs) that formulate U .S. positions that become the single U .S. votes on international committees. Joining ISEA gives companies opportunities to contribute to U .S. TAGs that look after their products. In a nutshell, expertise contributed by ISEA and its members provides a foundation for the international standards-drafting process, and membership in ISEA gives your companies a say in ISO standards affecting your products.

U

.S. TAG positions are carried forward to those who participate internationally. Because most ISO meetings are held in Europe, becoming directly involved in ISO standards deliberations requires a much greater commitment in terms of time and money. Participating at the international level — attending meetings in Europe and elsewhere around the globe — can be more cost-effective for multinational companies.

How do ISO standards for safety equipment

fit with ANSI standards?

U

.S. standards developers can introduce a U .S. standard into the ISO process to be adopted as an international standard. There is also a process by which member nations can adopt ISO standards as their national standards.

10

Safety Equipment Standatanda tandards : Your Keys to eys to Business Success

1

5

Where can I get a list of safety equipment standards

around the world?

ISEA maintains a database of safety equipment standards internationally, regionally and for other countries around the world. The only way to for a safety equipment manufacturer to gain access to this database, which is organized by product or country, is to join ISEA.

Conformity Assessment

How does a manufacturer demonstrate that its product conforms to a standard?

Conformity assessment is the process a manufacturer uses to demonstrate that a product conforms to the applicable standard. It involves product evaluation and testing to an established standard and providing a mark or some other indication of conformity.

Certification may be done by a government agency such as the NIOSH, U .S. F ood and Drug Administration or Mine Safety and Health Administration; the product manufacturer, either at its own facility or at a contract testing lab, or by an independent assessor.

Government certification programs exist in the U nited States mostly when public health and safety are involved. For example, NIOSH tests and certifies respirators and breathing apparatus.

However, manufacturers’ self-certification is the most common approach in the U nited States. Manufacturers test their products or have them tested and declare that they meet the standard. This declaration may be a label on the product — often in a form required by the standard — along with information provided in the packaging, literature and advertising.

11

INTERNATIONAL SAFETY EQU IPMENT ASSOCIATION

Where self-certification will not satisfy the market demand or regulatory requirements, manufacturers and users rely on third-party certification. In this case, an independent organization conducts testing of a product to see if it meets the performance requirements of a recognized standard. It also may require an assessment of the company’s quality systems to ensure that the manufacturer’s internal production controls are designed and operated so that every product that comes off the line will meet the standard’s requirements. When these conditions are met, the third party grants the manufacturer the use of its certification mark. Examples of third-party certifiers are the Safety Equipment Institute (SEI) and U nderwriters Laboratories (UL).

In the rest of the world, third-party certification for safety equipment is the norm. F or example, all personal protective equipment in Europe has to be tested and certified and carry the CE mark. Canada requires CSA certification. In the U nited States, some standards, such as NFPA standards for fire and emergency service equipment, require third-party certification as well.

12

Safety Equipment Standatanda tandards : Your Keys to eys to Business Success

December 2007

Work on the job provides a livelihood and professional pride. Work around the home gives satisfaction while adding beauty, comfort and pleasure to life.

Work cannot be done without the right tools. Most are purchased. They can be lost or damaged. All are replaceable.

But there are other tools in the kit — the most important ones. These come as standard equipment. They are the worker’s brain, the bones, the eyes, the ears, the hands and fingers, the feet, and the lungs. They also can be lost or damaged. And for the most part they are irreplaceable.

Unfortunately, work sometimes exposes these most important tools to the potential for loss or damage. In some cases, work hazards may be life threatening.

And when the potential for harm exists, safety equipment is the guardian. Members of the International Safety Equipment Association provide the barriers to keep the “standard equipment” ready to work when there is work to be done — and ready for all of the other good things that life has to offer.

On the Job or at Home,

Safety Equipment

Works while You Do

نوشتن نظر

نام شما:نظر شما: توجه : HTML ترجمه نمی شود!

رتبه: بد خوب

کد امنیتی را در کادر زیر وارد نمایید: